THE TYPICAL ALL-METAL HOTEND ASSEMBLY IT’S COMPOSED OF:

- NOZZLE

- HEAT-BLOCK WHERE THE ELETRICAL RESISTOR AND THE CONTROL TEMPERATURE THERMOCOUPLE ARE HOUSED (NOT ILLUSTRATED ON THE IMAGE)

- HEAT-BREAKER

- HEAT-SINK

- COOLING FAN TO COOL THE HEAT-SINK (NOT ILLUSTARTED ON THE IMAGE)

BEST REQUIRED PHYSICAL AND MECHANICAL PROPERTIES OF THE ILLUSTRATED ELEMENTS:

- HEAT BREAKER:

STICK SURFACE PROPERTIES VERY LOW WHEN IN CONTACT WITH PLASTICS

GOOD SURFACE HARDNESS

LOW THERMAL CONDUCTIVITY

- HEAT SINK:

HIGH THERMAL CONDUCTIVITY

HIGH THERMAL EXCHANGE SURFACE (THE BEST IN RELATION WITH THE AIR FLUX THAT CROSSES IT TROUGH THE COOLING FAN)

- HEAT BLOCK:

HIGH THERMAL CONDUCTIVITY

HIGH THERMAL STABILITY

- NOZZLE:

HIGH THERMAL CONDUCTIVITY

HIGH INTERNAL SURFACE HARDNESS

BEST SHAPE FOR FLUODYNAMIC FLUX, IN PARTICULAR WHERE THE SECTION CHANGE

BEST DESIGN FOR FLUODYNAMIC FLUX, IN PARTICULAR THE LENGHT AND THE SHAPE OF THE OUTFLOW HOLE

HIGHEST SURFACE HARDNESS AND HIGH THERMAL CONDUCTIVITY, WHERE THE INTERNAL SECTION CHANGE UNTIL THE OUTFLOW HOLE

BEST FRICTION COEFFICIENT CALIBRATION FOR ALL INTERNAL SURFACES WHERE SLIDES MELTED PLASTIC

ALL THESE FEATURES ARE WELL KNOW BY INDUSTRY EXPERT.

SOME CONSIDERATION ON THE TYPICAL ASSEMBLY OF ALL-METAL HOTEND:

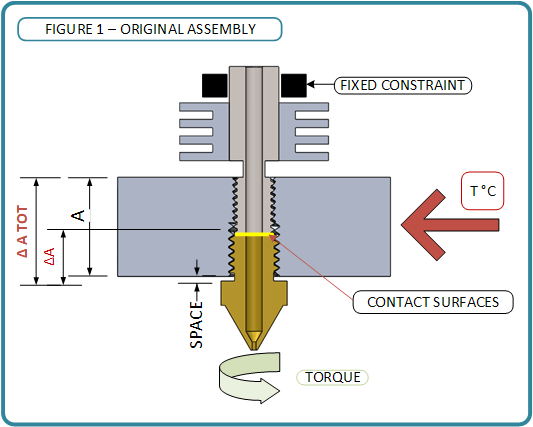

IN FIGURE 1, A TYPICAL ASSEMBLY IS SHOW, ESPECIALLY IN RELATION TO MY MACHINE (RAISE3D-PRO2) WICH I HAVE BEEN USING FOR MORE THAN 4 YEARS.

AT THE BEGINNING I HAD MANY PROBLEMS WITH USE, COMPARED TO THE PREDICTABLE, REPEATABLE AND RELIABLE EFFICIENCY OF A CNC MACHINE.

SO IN ADDITION TO DEVELOPING SOME PARTS FOR MY VERY INTENSE NECESSARY USE, I TRIED TO UNDERSTAND AS BEST AS I COULD ALL THE PROBLEMS AND POSSIBLE TECHNICAL DEFECTS.

CONCERNING FIGURE 1, WHICH ILLUSTRATES THE SECTION OF THE HOTEND MOUNTING, THE HEART OF THE MACHINE, I NOTICED SOME DESIGN DEFECTS AND, BY SOLVING THEM, I WAS ABLE TO REACH, UNTIL NOW, MORE THAN 20.000 HOURS OF CONTINUOUS PRINTING WITHOUT PROBLEMS.

LET’S TRY TO ANALYZE THEM CAREFULLY:

THE HOT-BLOCK HAS TWO DIFFERENT THREADED HOLES, ONE M5x0.8, SEAT OF THE HEAT-BREAKER AND, OPPOSITE TO THIS, ANOTHER M6x1 SEAT OF THE NOZZLE.

FOR ASSEMBLY, THE INSTRUCTIONS REPORTED TO SCREW BOTH UNTIL THEY CONTACTED WITH EACH OTHER, PAYING ATTENTION, WHILE TIGHTENING THE NOZZLE, THAT SUCH CONTACT DID NOT OCCUR BETWEEN IT AND THE HEAT-BLOCK.

IN THIS WAY IT WAS CERTAIN THAT, WHILE APPLYING THE TIGHTENING TORQUE ON THE NOZZLE, THE CONTACT SURFACES WERE THOSE INTENDED FOR THE TRANSITION FROM SOLID TO FLUID OF THE MATERIAL TO BE EXTRUDED.

THE ONLY WAY (AT LEAST POSSIBLE WITHOUT PARTICULAR SELF-BUILT EQUIPMENT OR WITHOUT ARRANGEMENTS WITH RISK OF BURNS) WAS A COLD ASSEMBLY WHICH UNFORTUNATELY COULD NOT GUARANTEE ANY ELASTIC ELEMENT WHICH COULD ABSORB, THROUGH ITS DEFORMATION, THE LINEAR AND VOLUMETRIC EXPANSIONS RESULTING FROM THE TEMPERATURE INCREASES (UP TO 310 °C…)

AFTER SOME SIMPLE CALCULATIONS, I WAS ABLE TO UNDERSTAND THAT, WITH A COLD ASSEMBLY, THE ONLY ELEMENTS THAT WERE ABLE TO DEFORM ELASTICALLY UNDER THE TIGHTENING TORQUE OF THE NOZZLE, WERE THE CONTACT SURFACES BETWEEN IT AND THE HEAT-BREAKER AND SOME THREADS ON THE HEAT-BLOCK IN ALUMINIUM (!).

MORE OR LESS THE CALCULATED EQUIVALENT DEFORMATION, REGARDING A MAXIMUM TIGHTENING TORQUE REFERRED TO THE MAXIMUM RESISTANT ANNULAR SECTION OF THE NOZZLE, HAD A VALUE EQUAL TO APPROXIMATELY 0.03-0.035 mm. (I HOPE IN LINEAR ELASTIC STATE).

THE DIMENSION “A” IN THE FIGURE REPRESENTS THE HEIGHT OF THE HEAT-BLOCK AND, IN MY CASE, IS EQUAL TO 12 mm.

CONSIDERING THAT THE HEAT-BLOCK IS MADE OF ALUMINUM, IT IS SUFFICIENT TO MULTIPLY ITS HALF HEIGHT BY ITS LINEAR THERMAL EXPANSION COEFFICIENT FOR THE TEMPERATURE DIFFERENCE TO UNDERSTAND HOW, IN ADDITION TO CERTAIN TEMPERATURES, IT IS VERY LIKELY TO HAVE A DETACHMENT BETWEEN THE CONTACT SURFACES OF THE NOZZLE AND THE HEAT-BREAKER.

THE CONSEQUENCES ARE KNOWN, THE EXTRUSION PROCESS CAN BE INTERRUPTED CAUSING THE TYPICAL CLOGGINGS IF NOT EVEN LEAKAGES OF LIQUID MATERIAL ESPECIALLY THROUGH THE THREADED PART OF THE HEAT-BREAKER.

∆A MAX= 6X0.000024X∆T

WHERE ∆A MAX MUST BE, APPROXIMATELY, MAXIMUM 0.035 AND CONSEQUENTIALLY THE MAX AFFORDABLE ∆T IS:

∆T=0.035/6X0.000024= ABOUT 250-260°C IN RELATION TO HOW IS GOOD THE PRATICAL CHARGE OF THE ELEMENTS ELASTIC DEFORMATION. – CAN WILL BE ONLY 190-230°C….

YOU CAN UNDERSTAND, IN ANY CASE, HOW THE SYSTEM IS IN A VERY UNSTABLE STATE.

IN FACT, WHEN I GROWED UP THE TEMPERATURE UP TO 250-260°C, IF I KEEP IN HAND THE TERMINAL WIRE OF THE TERMISTOR, I COULD ROTATE THE WHOLE HOTEND AROUND THE HEATBREAKER WITHOUT ANY EFFORT: A SURE SIGN THAT THE CONTACT SURFACES BETWEEN THE NOZZLE AND THE HEAT-BREAKER HAD LOST ANY ADHESION AND CONTACT EVEN IF MINIMAL.

IN THESE TYPICAL HOTEND ASSEMBLY, THE ONLY SOLUTION TO HAVE A MINIMUM OF RELIABILITY IS A HOT ASSEMBLY AT AT LEAST 200°C DUE TO THE STRESS INDUCED IN THE TRHEAT HOLE IN ALUMINIUM, WHICH IS DEFINITELY NOT POSSIBLE AND DANGEROUS ON MY MACHINE.

HOW TO SOLVE?

OPTIMIZED HOTEND ASSEMBLY

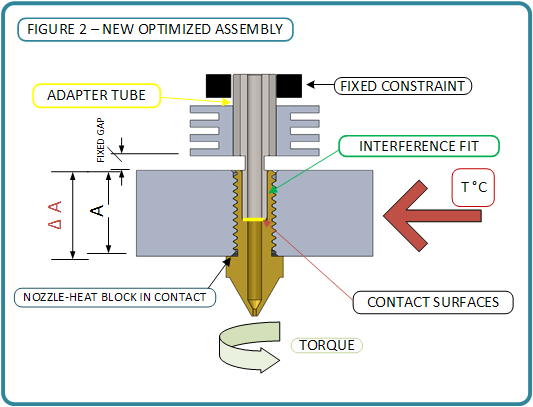

FIGURE 2 SHOWS HOW I SOLVED THE PROBLEM 4 YEARS AGO AND WHICH HAS ALLOWED ME TO PRINT, WITHOUT ANY TYPE OF PROBLEM, FOR MORE THAN 20.000 HOURS UNTIL NOW, WITH ALL TYPE OF FILAMENTS, IN PARTICULAR THE TECHNICAL ONE, CHARGED AND NOT CHARGED, ALSO THANKS TO THE ESSENTIAL Y-SHAPED SiC TIP.

WITHOUT THE LATTER, IN ANY CASE, I WOULD HAVE HAD TO REPLACE THE NOZZLE AND UNASSEMBLY THE HOTEND I DON’T KNOW HOW MANY TIMES.

LET’S TRY TO ANALYZE THE SIMPLE SOLUTION:

IN THIS CASE, AS IS EASY TO UNDERSTAND, THE VOLUMETRIC AND LINEAR THERMAL EXPANSIONS OF THE HEAT-BLOCK, GIVEN THE NEW CONSTRAINTS, WILL BE DISTRIBUTED AROUND ITS CONTOURS, WITHOUT AXIALLY INFLUENCED THE CONTACT SURFACES BETWEEN THE NOZZLE AND THE HEAT-BREAKER.

THE NOZZLE IS COMPLETELY SCREWED ONTO THE HOT-BLOCK, UNTIL COMPLETE CONTACT WITH IT, THROUGH A COMPLETE M6x1 THREAD.

THE HEAT-BREAKER IS MOUNTED ON IT COLD, WITH AN EASILY CALCULABLE RADIAL INTERFERENCE COUPLING AND, ABOVE ALL, INVOLVING EXTREMELY SMALLER DIMENSION.

NOW LET’S SEE THE VALUE OF THE INTERFERENCE WHICH CAN ENSURE A STABLE AND CERTAIN CONNECTION BETWEEN THE TWO ELEMENTS WHEN THE TEMPERATURE REACHES 310°C (MAXIMUM TEMPERATURE OF MY MACHINE – RAISE3D-PRO2)

THE NOZZLE IS MADE OF BRASS AND ITS LINEAR THERMAL EXPANSION COEFFICIENT IS 0.000019 WHILE I HAVE MADE THE HEAT-BREAKER IN AISI316L AND ITS LINEAR THERMAL EXPANSION COEFFICIENT IS APPROXIMATELY 0.000017 AND THE COUPLING DIAMETER BETWEEN THEM IS 3.5 mm(D).

NOMINAL PERIMETER OF THE DIAMETER 3.5mm:

P = πx3.5mm= 10.99mm

INCREASING PERIMETERS@310°C:

∆PERIMETER (HEAT-BREAKER- AISI316L) πxD (mm)x0.000017×310(°C) = 0.058mm

∆PERIMETER (NOZZLE – BRASS CW617N) πxD (mm)x0.000019×310(°C) = 0.062mm

TOTAL LENGTH PERIMETERS @310°C

PERIMETER HEAT-BREAKER = 10.99+0.058mm=11.048

PERIMETER NOZZLE = 10.99+0.062mm=11.053

RESULTING DIAMETERS:

D(EXT) HEAT-BREAKER= 11.048/π = 3.5184

D(INT) NOZZLE = 11.053/π = 3.5199

∆D = 3.5199-3.5184 = 0.0015mm

AS WE CAN SEE IS ENOUGH AN INTERFERENCE OF 0.002mm AT COLD, TO COMPLETELY ENSURE THE CERTAIN CONTACT BETWEEN THE HEAT-BREAKER AND THE NOZZLE AT THE MAXIMUM TEMPERATURE OF 310°C.

IN THIS CASE THE VERY IMPORTANT CONTACT PLANAR SURFACES BETWEEN THE HEAT-BREAKER AND THE NOZZLE CAN’T SEPARATE ONE WITH THE OTHER FOR NO REASON AND THE CLOGGING PROBLEMS ARE COMPLETELY SOLVED.

IN ORDER NOT TO MODIFY THE FIXED CONSTRAIN ON MY MACHINE, I MAKE A SIMPLE ADAPTER ALWAYS IN AL ALLOY 6083 SERIES SHAPED AS A TUBE WITH A A MINIMAL TOLERANCE.

AFTER SCREWING THE NOZZLE COMPLETE WITH HEAT-BREAKER ON THE HEAT-BLOCK, JUST COLD-INSERT THE ADAPTER ON THE TERMINAL PART OF THE HEAT-BREAKER AND FIX IT WITH THE SCREW ON THE HEAT-SINK.

TO POSITION THE HEAT-SINK AT THE CORRECT DISTANCE, A CALIBRATED THICKNESS IS SUFFICIENT TO BE PLACED BETWEEN IT AND THE HEAT-BLOCK, BEFORE FIXING IT WITH THE SCREW, AS THIS DISTANCE IS FIXED AND WELL-DETERMINED IN THIS TYPE OF ARCHITECTURE.

BEST IN CLASS

“THE ONLY ONE FOREVER”