“IT WORK IS NOT ENOUGH, IN WHAT WAY IT WORK IS THE MUST”

TO HAVE A GOOD OUTFLOW FLUX FOR THE BEST PRINTING QUALITY, THE FLUX ITS MUST RESPECT THE BERNOULLI LAW OF “LAMINAR FLUX” (UNDER 2300 BERNOULLI NUMBER).

SIMPLIFYNG, THE LAMINAR FLUX HAPPENED WHEN ALL THE PARTICLES OF THE FLUID THAT SLIDES INSIDE A SURFACE, DON’T CHANGE ITS DIRECTION RESPECT THE DIRECTION OF THE SAME SURFACE.

AND AGAIN, FOR A PERFECT IDEAL FLUID THE FRICTION COEFFICIENT ON THE CONTAINED SURFACE MUST BE THE MINIMUM. (ZERO IF IS POSSIBLE)

OTHERWISE, IF THE PARTICLES CHANGE DIRECTION RESPECT TO THE DIRECTION OF THE CONTAINED SURFACE, TURBOLENT PHENOMENA CAN WILL BE PRODUCED WICH DISTURB THE EFFICENCY AND REGULARITY OF THE FLOW ITSELF.

THIS PROBLEM CAN WILL HAPPENED FOR A WRONG CONTAINED SURFACE GEOMETRY AND A BAD FRICTION COEFFICIENT ON IT.

THE NOZZLES OF FDM 3D PRINTING TECHNOLOGY HAVE AN INLET HOLE FROM 1.75 TO 2.85 MM (THE TOO USED FILAMENTS) AND AN OUTFLOW HOLE FROM 0,1 TO PLUS THAT 1 MM.

SO, THE MELTED FLUID THAT PASS TROUGH, AT THE OUTLET HOLE, MUST CHANGE ITS SECTION DRASTICALLY.

IN THIS WAY, EXACTLY ON THE PLANE WHERE THIS SECTION CHANGE AND ON THE PLANE WHERE IT FLOW OUT, IS THE SITES WHERE THE TURBOLENCE EFFECT IT CAN FORM WITH, CONSEQUENTELY, UNWANTED EFFECTS (AND, UNFORTUNATELY, NOT VISIBLE) ESPECIALLY WITH REGARD TO POSSIBLE CLOG OR IRREGULAR FLOW.

FURTHERMORE, THE PLASTIC FILAMENTS USED HAVE VERY DIFFERENT INTERNAL VISCOSITY (AT DIFFEREN MELTED TMPERATURE) AND DIFFERENT EXTERNAL FRICTION COEFFICIENT.

IN THIS WAY, IT COULD BE SAID THAT FOR A PERFECT PRINT, THE INTERNAL GEOMETRY AND THE FRICTION COEFFICIENT OF THE INTERNAL CONTAINED SURFACE OF THE MELTED PLASTIC FILAMENTS SHOULD BE VERY DIFFERENT, MAYBE THE BEST FOR ANY SIGLE FILAMENTS AN MATERIAL.

IN PRACTICE, AS FOR ALL, MUST HAVE A VERY GOOD COMPROMISE THAT CAN WILL WORK EVER WELL IN THIS DIFFERENT CONDITIONS.

THIS COMPRIMISE IS UNDERSTANDABLE AND RIGHT BUT MUST BE STUDIED VERY WELL AND NOT IMPROVISE IT ONLY FOR THE “IMPRESSIONABILITY WITHOUT KNOWLEDGE” OF THE POTENTIAL MARKET.

HOWEVER, MANY STUDIES HAVE BEEN CARRIED OUT REGARDING THE GEOMETRIC PARAMETERS OF THE INTERNAL SURFACE TO RESPECT A LAMINAR FLOW, IN FACT, MANY BRASS OR STEEL OR HARDENED STEEL NOZZLES WHERE, DUE TO THE ONE OF THE CHEAP AND SIMPLIEST MATERIALS TO WORK ON, WE CAN FIND THE RIGHT SOLUTION ABOUT.

UNLUCKY, ITS DURABILITY AND CONSEQUENTELY ITS REPEATIBILTY AND THE PRINT QUALITY IS NOT AFFORDABLE

SO, WE CAN AFFIRM THAT THE RIGHT INTERNAL GEOMETRY SURFACE (ALMOST ALWAYS…) OF THE BRASS NOZZLES AS FOR THE STEEL AND HARDENED STEEL NOZZLES CAN SATISFY A GOOD LAMINAR FLUX.

OTHERWISE, FOR IMPROVE THE DURABILITY, THE REPEATIBILTY, AND THE PRINT QUALITY MANY OTHER FIRM TRY TO DEVELOP THE COMPOSITE NOZZLES WITH A POINT IN HARD MATERIALS, VERY DIFFICULT TO MADE AND WORK ON.

UNLUCKY, ABOUT THEM, THE OUTFLOW SECTION (THE TOO IMPORTANT TO HAVE AN OUTFLOW LAMINAR FLUX), DESPITE TO ITS HARDNESS AND, IN SOME CASE (PCD DIAMOND AS AN EXAMPLE), VERY HIGH THERMAL CONDUCTIVITY, HAVE THE WORSE GEOMETRY.

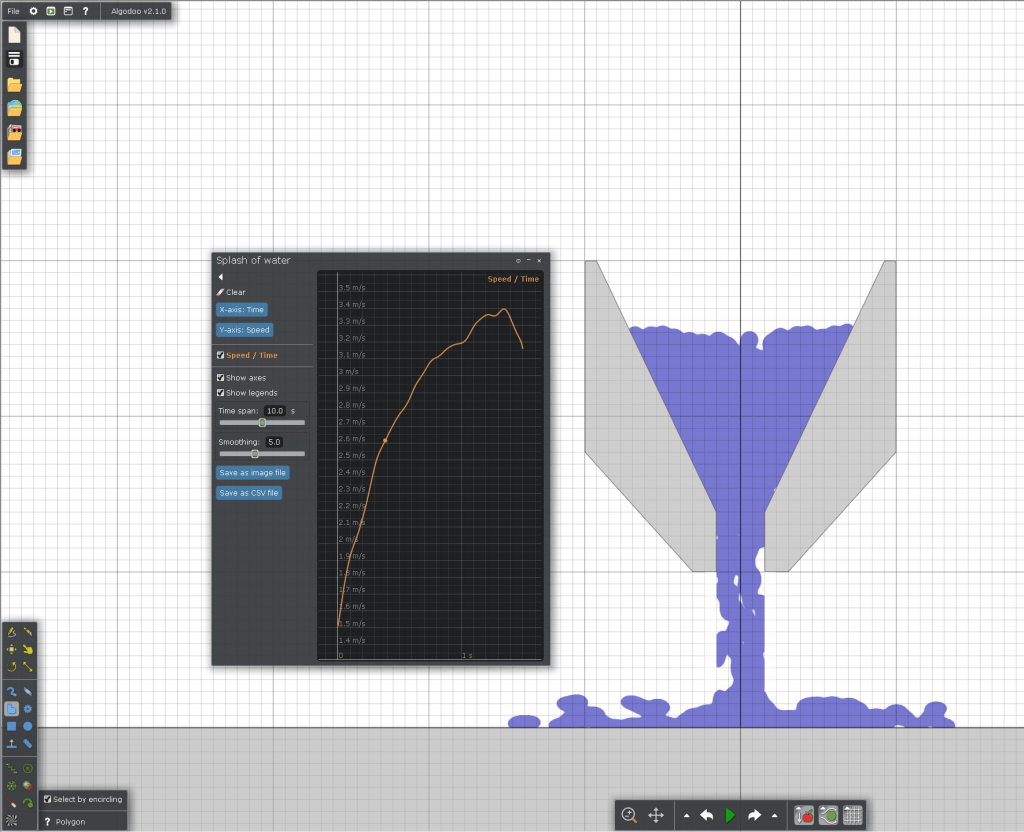

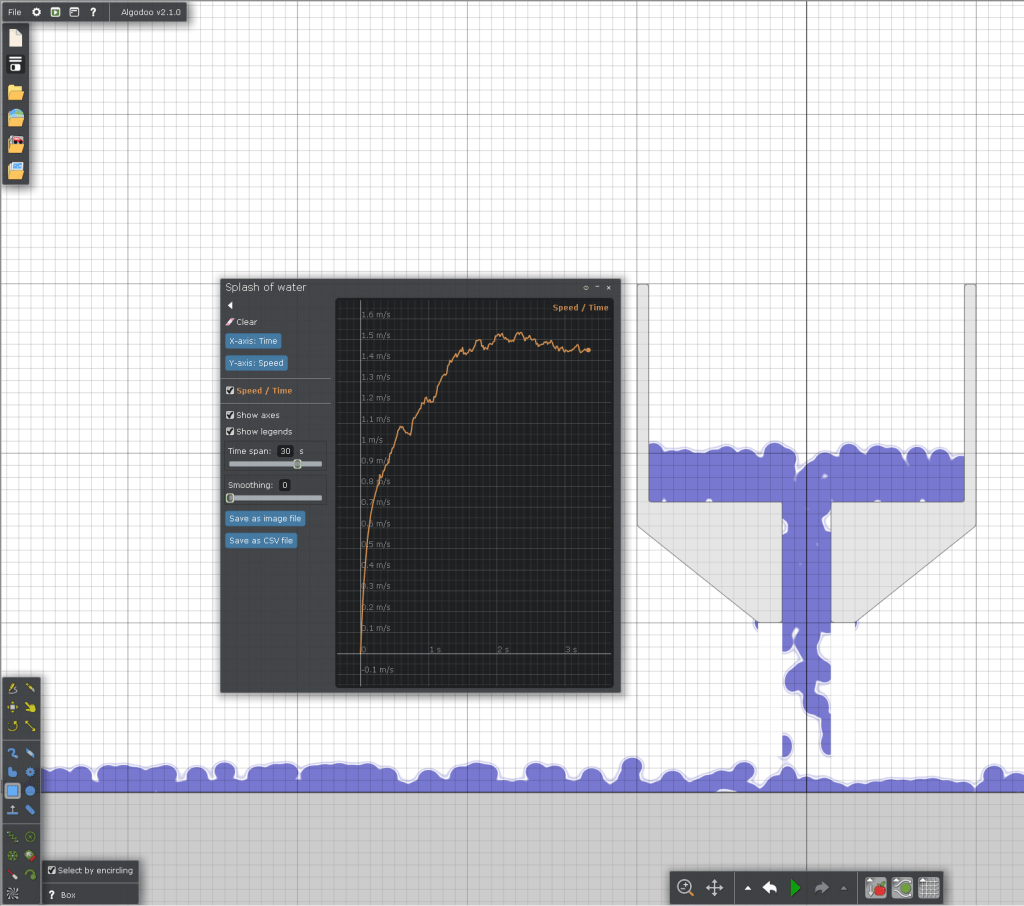

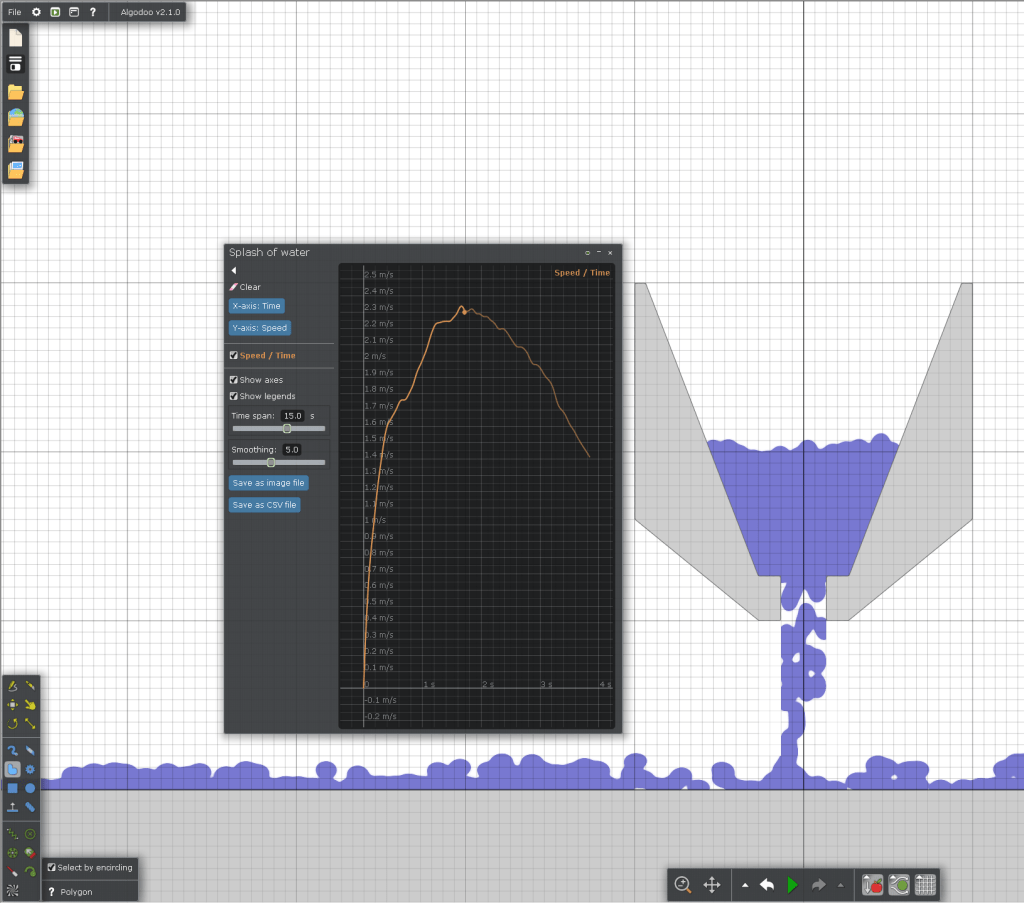

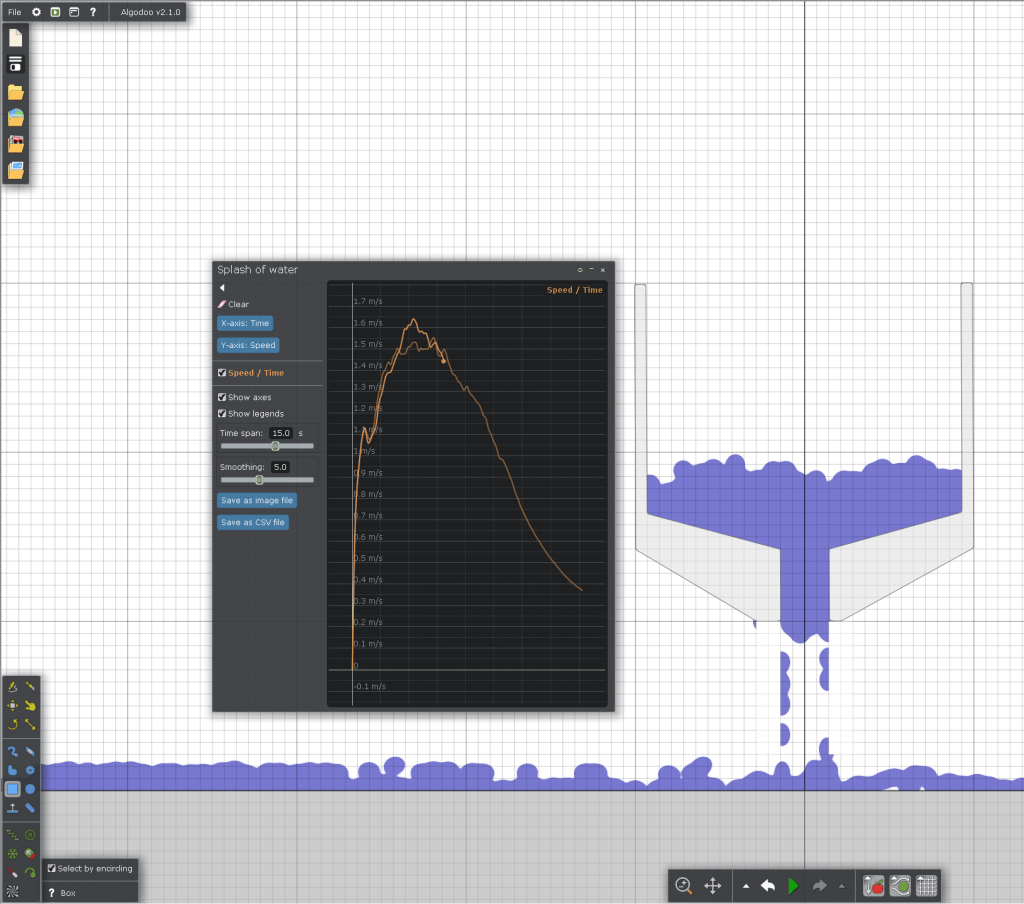

HERE SOME EXAMPLE FROM A SIMPLE SIMULATION MADE WITH ALGODOO ( YOU CAN DOWNLOAD AND USE FREE) USING WATER AS FLUID AND GRAVITY AS FORCE . THE FLUODYNAMIC ISSUE , DON’T SUFFER THE SCALE MODEL CONDITION, SO IN THIS WAY , WITH A MINUM RESPECT OF PROPORTIONS IS SIMPLE TO OBTAIN AN AFFORDABLE RESULT :

AS YOU CAN SEE THE SPEED OF THE FLUID IT’S HEAVILY INFLUENCED BY THE GEOMETRY OF TEH CONTAINMENT SURFACES AND DECREASE BY UP ( OR MINUS) AN HALF COMPARED TO A CORRECT GEOMETRY. CONSEQUENTLY THE TIME FOR THE TOTAL OUTFLOW ALSO INCREASES PROPORTIONALLY.

THE QUOTE OF THE ANGLE “A” AND THE LEGHT OF THE OUTEL HOLE IS VERY IMPORTANT TO OBTAIN THE LAMINAR FLUX OF THE MELTED FILAMENTS.

OTHERWISE ALSO THE FRICTION COEFFICIENT OF THE SURFACE IN CONTACT WITH THE MELTED FLUID IS VERY IMPORTANT FOR THIS MATTER AND MUST NOT BE THE MINIMUM POSSIBLE (!): IF THE FRICTION COEFFICIENT OF THE CONTACT SURFACE IS LESS THAT THE INTERNAL DYNAMIC FRICTION OF THE FLUID THE LAMINAR CONDITION CAN’T BE SATISFY THE SAME BECAUSE THE INTERNAL PARTICLE OF THE FLUID CAN WILL HAVE A SPEED LESS TO THE PARTICLE IN CONTACT AND CREATE A BAD TURBOLENCE EFFECT THE SAME AT THE OUTLET HOLE.

AS IS POSSIBLE UNDERSTAND, THE DESIGN OF A GOOD 3D FDM PRINTING NOZZLE IS NOT SO SIMPLE AND IS NOT ONLY FOR DURABILITY BUT FOR HAVE THE BEST CONTINUOS PERFORMANCE AS FOR A CNC CUTTER OR OTHER PROFESSIONAL INSTRUMENT.

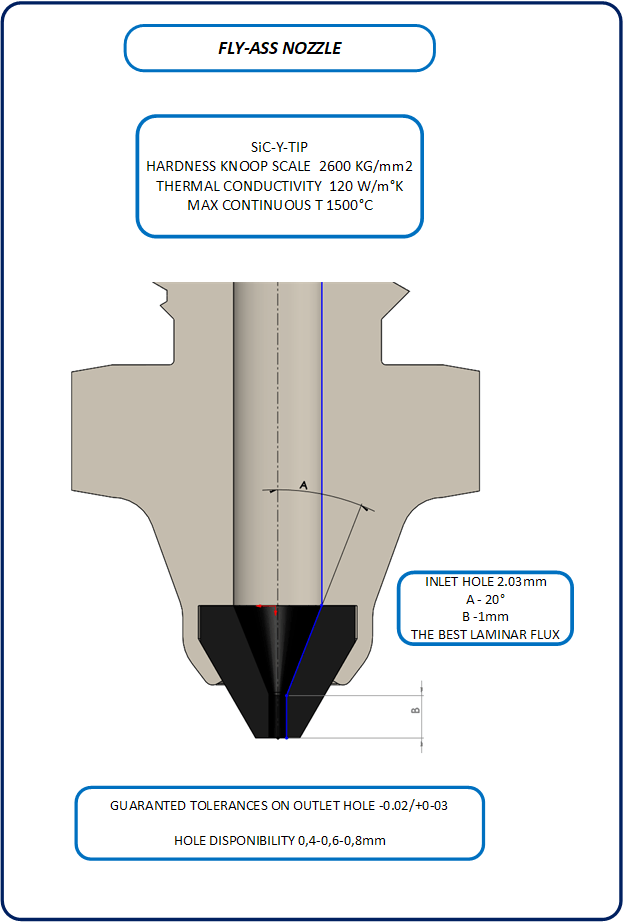

FLY-ASS NOZZLE

THE COMPOSITE FLY-ASS NOZZLE TRY TO SOLVE ALL THIS ISSUE.

FOR SOLVE ALL THE ILLUSTRATED PROBLEM, IS COMPOSED FROM A PART IN BRASS (OR, FOR TEMPERATURE UP TO 500°C, IN COPPER-CHROME-ZIRCONIA ALLOY) AND AN END POINT IN SILICON CARBIDE, THE SECOND MATERIAL FOR HIGH HARDNESS (MOHS SCALE 9,5 – 2600 KG/mm2) AFTER DIAMOND AND WITH A THERMAL CONDUCTIVITY THE SAME AS BRASS- 120W/m°K- (TOO HIGH IS NOT USEFULL AND DON’T GIVE ANY BETTER RESULT).

THE GREAT ADVANTAGE IS THAT FOR THIS TYPE OF MATERIAL WE CAN OBTAIN A PERFECT FLUODYNAMICS GEOMTRY, THE SAME AS FOR BRASS, STEEL OR HARDENED STEEL PART, WITHOUT ANY SORT OF OBSTACOLE.

THE SILICON CARBIDE IS NOT SIMPLE TO WORK ON BUT WITH A MASTER PARTNER, AFTER MANY TRY, WE ARRIVED TO THE BEST PRODUCTION SOLUTION ALSO WITH AN AFFORDABLE AND COMPLETE REPEATABLE PROCESS.

THE DESIGN AND THE PRODUCTION OF THE INTERNAL CONE WITH A SPECIAL MICRO GEOMETRY WAS ALSO A GREAT DEVELOPMENT OF THE GLOBAL PERFORMANCE.

THE ASSEMBLY OF THE METALLIC AND CERAMIC PARTS, IS MADE BY CNC MACHINE WITH A TOLERANCE AND A REPEATABLE OF 0.01mm.

THIS SPECIAL ASSEMBLY PERMIT TO ADAPT THE TECHNOLOGY OF FLY-ASS NOZZLE TO ALL THE TYPE OF GEOMETRY AND MEASURE ALSO IN NON CIRCULAR PART.

AFTER THE ASSEMBLY, FOR THE BEST ANTI CORROSIVE PROTECTION OF THE METALLIC PART AND, FIRST, FOR THE BEST CALIBRATION OF THE FRICTION COEFFICIENTS DESCRIBED ABOVE, THE FLY-ASS NOZZLES ARE SUBJECTED TO A NICKEL PLATED CHEMICAL TREATMENT WITH A THERMAL POST-TREATMENT UNDER CONTROLLED NITROGEN ATMOSPHERE FOR 4 HOURS AT 340°C (NIPLATE 600 TREATMENT).

ALL THE NOZZLES ARE CONTROLLED ONE BY ONE WITH A SPECIAL AND VERY FAST BUT 100% AFFORDABLE CONTROLLED PROCEDURE.

THE FLY-ASS NOZZLE, AS MENTIONED BEFORE, CAN ALSO MADE IN COPPER-CHROME-ZIRCONIA ALLOY FOR HIGH TEMPERATURE REQUEST (UP 500°C), IN ANY CASE THE SILICON CARBIDE POINT CAN WORK CONTINUOSLY @1500°C.

THE SILICON CARBIDE END POINT AND THE NIPLATE TREATMENT ARE ALL TWO FDA APPROVED.

FLY-ASS NOZZLES WAS USED WITH ALL TYPE OF FILAMENT AND OBTAINED WITH ALL THE BEST PERFORMANCE, IS ALSO USED FOR HIGH SPEED PRINT ALSO WITH CARBON AND GLASS FIBER CHARGED FILAMENTS.

FOR MY PERSONAL INTENSIVE USE, I CONTROLLED 1 NOZZLES UNDER MICROSCOPE AFTER 20.000 HOURS OF WORKING WITH ALL TYPE OF FILAMENTS AND I DON’T FOUND ANY TYPE OF WEAR AND WITH THE BEST PRINTING QUALITY.

FOR THE MOMENT, FLY-ASS SILICON CARBIDE END POINT IT IS AVAILABLE ONLY FOR 1.75 mm FILAMENTS.

“THE OLY ONE FOREVER”